Shopping Cart

(4)

Subtotal:

$212.00

Shipping:

$5.00

Total:

$217.00

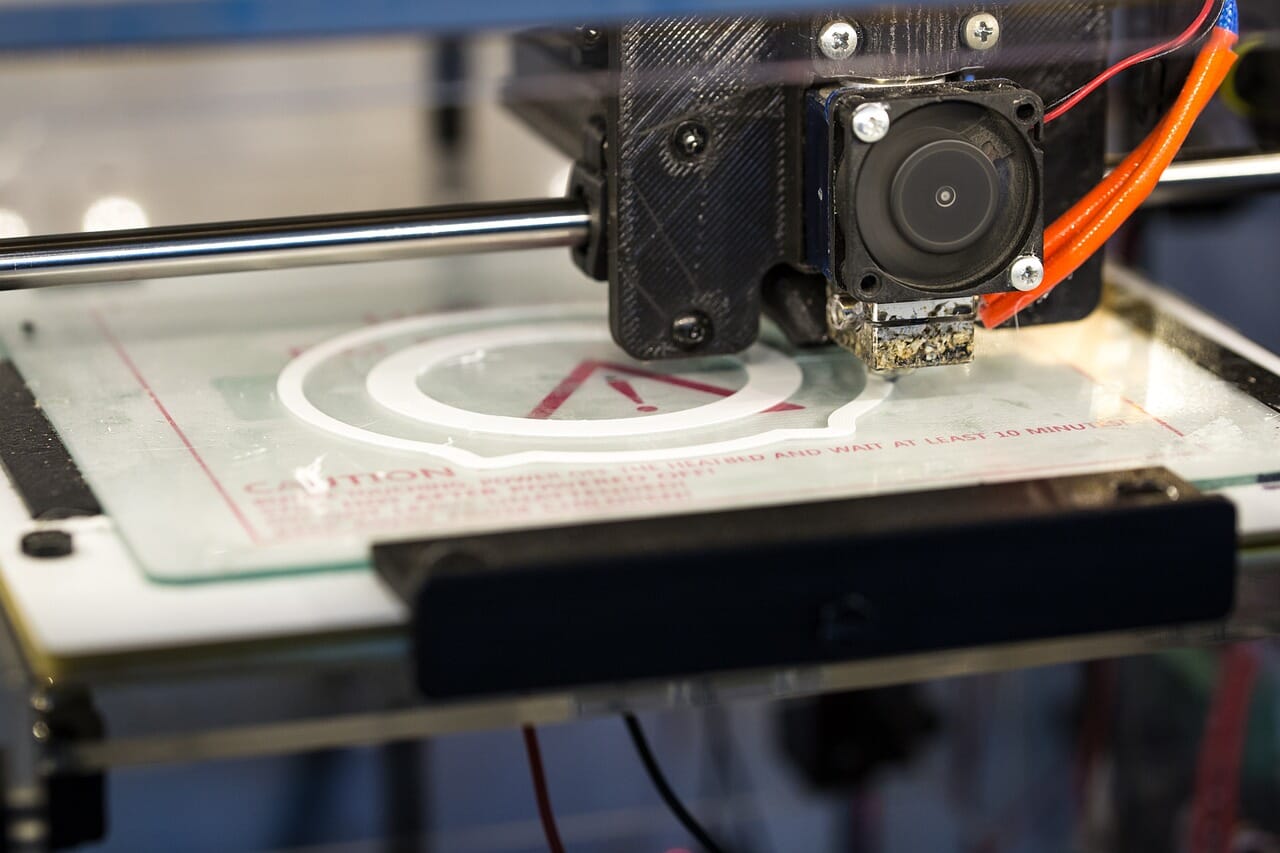

In recent years, the process and development of 3D printing has revolutionized manufacturing, prototyping, and art, by turning complex designs on the computer into a reality. While there are a lot of factors that make 3D printing possible, one of the crucial components is filament—the physical material used to create these three-dimensional objects. There are many types of 3D printer filament available on the market, each with its own properties, advantages, and drawbacks, it can be challenging to select the right one for your project. Let’s explore common types of filament along with their pros, cons, and their best uses.

PLA is a popular type of 3D printer filament due to its ease of use and environmental friendliness. Made from renewable resources, it’s appealing to many because it’s biodegradable and produces minimal odor during printing. We often recommend it to beginners because it prints at relatively low temperatures and doesn't require a heated bed, reducing potential warping issues.

However, PLA's lower heat resistance means it's unsuitable for high-temperature applications. It's also less durable and impact-resistant compared to other filaments and can be brittle, making it less ideal for functional parts subjected to stress. Ultimately, this type of 3D printer filament is great for creating decorative items, models, toys, and prototypes that don't require high strength or temperature resistance. PLA is also considered ideal for aesthetic designs like vases, figurines, and cosplay props. However, it shouldn't be used for functional parts exposed to heat or stress, such as automotive components or outdoor items, as it can warp or degrade over time.

Known for its strength and durability, ABS is a type of filament for 3D printing that is often utilized for making functional parts. It has higher heat resistance than PLA and can be post-processed with acetone to achieve a smooth finish. The ABS type of 3D printer filament excels in creating functional parts like automotive components, electronic housings, and appliance parts due to its toughness and heat resistance. It's also widely used for making custom tools, enclosures, and structural parts in 3D printing, thanks to its excellent machinability and ease of post-processing. Additionally, ABS filament can be used to create intricate prototypes and mechanical parts that require a combination of rigidity and flexibility.

The main drawbacks of ABS are the unpleasant fumes it emits during printing, which require proper ventilation, and its tendency to warp, necessitating a heated bed and enclosure. ABS may be a more challenging type of 3D printer filament to work with than PLA but offers significant benefits for more demanding applications.

PETG is different from other 3D printer filaments as it combines the ease of printing of PLA with the strength of ABS. It offers good chemical resistance, minimal warping, and produces little to no odor during the printing process. Transparent variants are also available, making PETG filaments attractive to use for aesthetic applications. PETG is generally considered a good option for beginners due to its ease of printing and balanced properties. However, to print successfully with PET, some knowledge of bed adhesion, proper temperature settings, and cooling is required. Understanding how to prevent warping and stringing is also important for achieving high-quality prints.

If mastered, users find this type of printer filament excellent for producing durable, impact-resistant objects like mechanical parts, protective components, and water-resistant items.

Forge PLA+ is a different 3D printer filament, specifically designed to offer enhanced durability and strength compared to standard PLA, making it ideal for functional parts that require greater resilience. It's an excellent choice for those ready to advance from basic PLA, as it provides more robust mechanical properties suitable for functional parts and prototypes. Forge PLA+ filament is ideal for hobbyists and professionals looking to create stronger, more heat-resistant designs without the complexity of printing with more advanced materials like ABS or PETG.

It combines the ease of printing associated with regular PLA—such as minimal warping and no need for a heated bed—with improved mechanical properties, including better impact resistance and, in some cases, higher heat tolerance. This makes Forge PLA+ a popular type of 3D printer filament for projects where added durability is essential, without the complexity of more advanced filaments like ABS.

Leftover PLA from 3D printing projects is a common issue, and the remnants, often in the form of small spools, failed prints, or support structures, can accumulate over time. While PLA is biodegradable and more environmentally friendly than other plastics, discarding these leftovers still contributes to waste.

That’s why we make a point to recycle all of the unused filament, to create what we call the leftover spools, an environmentally conscious type of filament for 3D printing. At PrintBed, we are especially proud to offer our Mini PLA Leftovers to help do our part to help the environment and take progressive strides in the development of 3D printing technology. However, it is important to note that because our Mini PLA Leftovers are made from recycled material, the colors may differ batch-to-batch, which makes it the perfect material to use for practice or when color doesn’t necessarily matter.

Choosing the right filament for your 3D printing project depends on understanding the material's properties and how they align with your specific needs. Whether you're a hobbyist looking for easy-to-use materials or an engineer needing robust, durable filaments, there’s a wide array of options to explore. Experimenting with different types of 3D printer filaments can help you discover the best material for your projects, ensuring high-quality prints every time. At PrintBed, we guarantee the best quality of different types of 3D printing filaments with flawless coloring and perfect spooling every time.

At PrintBed, we place customer satisfaction at the heart of everything we do. That’s why we’re dedicated to providing the highest quality 3D filament on the market, ensuring consistent coloring and perfectly wound spools every time.

No matter what your project requires, PrintBed delivers top performance and outstanding customer service, making sure all your needs are met. We love connecting with our customers, so tag us on social media to share your projects and 3D printing tips! Start your next creation with PrintBed today!

Our Stores